Introduction

I attended a two-day 3D printing workshop in late 2025, led by an expert in additive manufacturing, modeling, and machining. The workshop provided an intensive overview of how 3D printing is transforming prototyping and production. My goal was to gain exposure to various 3D printing technologies and understand their practical applications in design and engineering through demonstrations and hands-on activities.

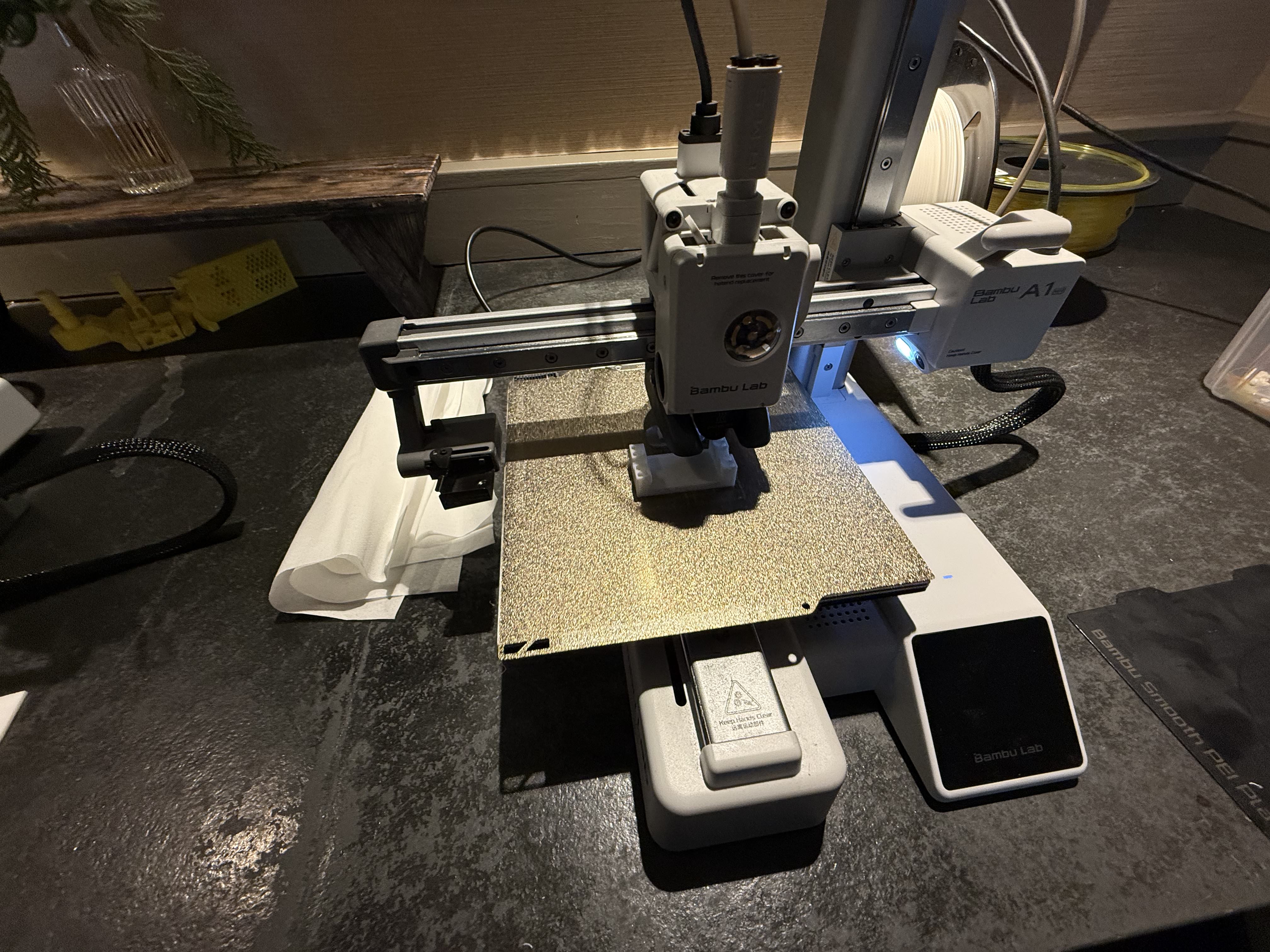

One of the 3D printers

Workshop Overview

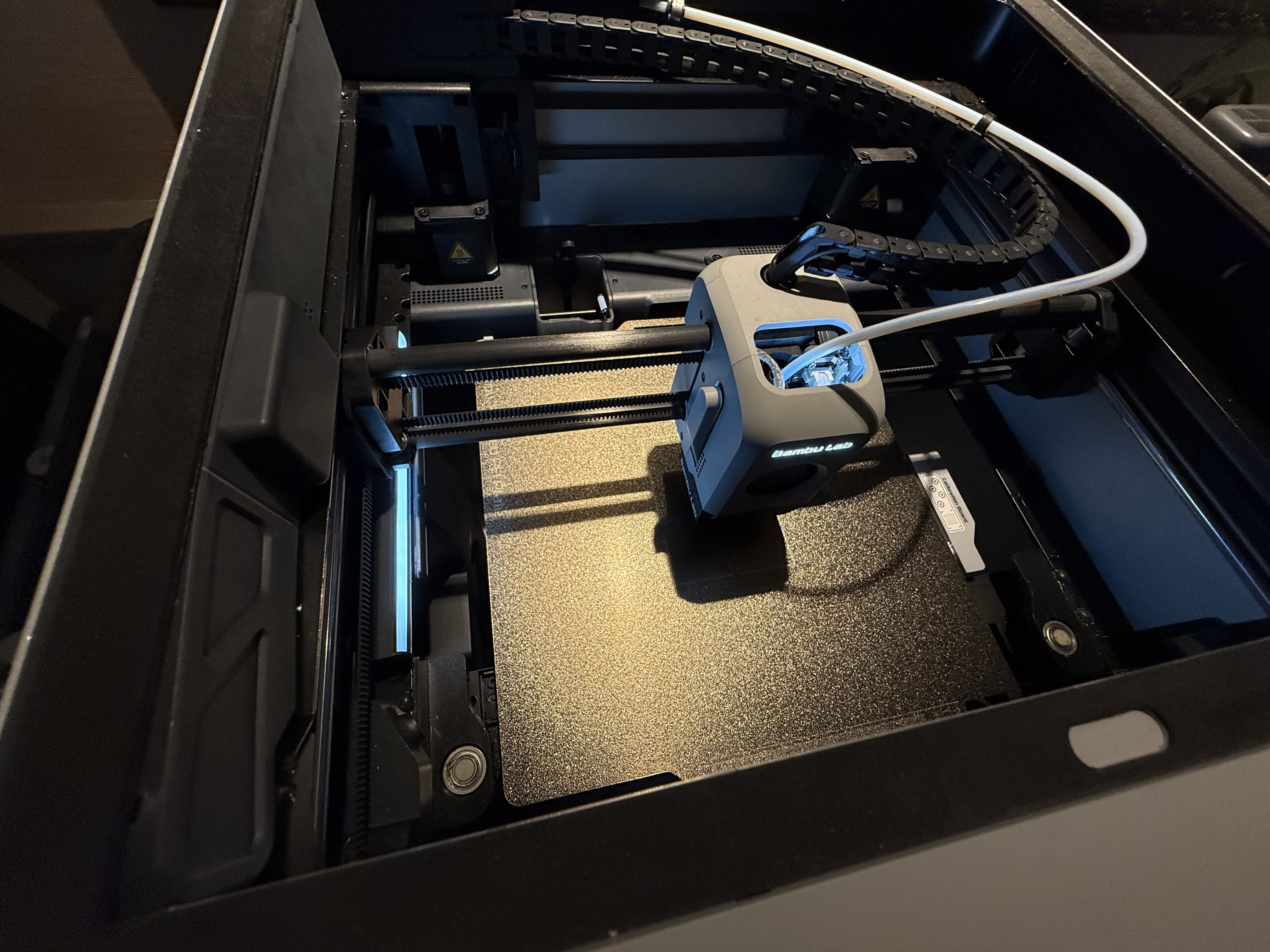

The workshop was structured around focused demonstrations, hands-on sessions, and expert insights delivered over two days. Participants observed different types of 3D printers including FDM and SLA machines, learning about their operational differences and ideal use cases. The sessions covered 3D modeling basics, slicing, printer setup, and post-processing techniques, offering a solid conceptual foundation in additive manufacturing.

Technologies and Skills Introduced:

- Introduction to CAD software such as Fusion 360 and Tinkercad

- Overview of FDM and SLA 3D printing technologies

- Material properties including PLA, ABS, and resin types

- Use of slicing software like Cura and PreForm

- Post-processing methods including sanding, curing, and painting

- Design principles tailored for additive manufacturing

another fancy printer

Design Demonstrations

During the workshop, the instructor demonstrated the design and printing of various objects, ranging from simple geometric shapes to functional prototypes like phone stands and mechanical parts. One of my personal projects was designing a custom battery clip for my robot, which required careful consideration of dimensions, flexibility, and secure mounting. Challenges such as optimizing support structures and balancing print speed with quality were discussed. These demonstrations highlighted key considerations in 3D printing workflows.

Technical Insights and Troubleshooting

The workshop covered common technical challenges including adhesion failures, warping, and layer misalignment. Participants learned troubleshooting strategies such as adjusting bed leveling, modifying print settings, and experimenting with different materials. The instructor shared professional tips for diagnosing and resolving print errors.

Common Issues and Solutions:

- Improving bed adhesion using glue sticks and heated beds

- Addressing layer separation by optimizing print temperature and speed

- Designing effective support structures to minimize material waste

- Mitigating warping through enclosure use and proper cooling

working on the design

Applications and Future Potential

The workshop provided insight into the expanding role of 3D printing in industries such as healthcare, aerospace, and custom manufacturing. The technology's potential for rapid prototyping and low-volume production was emphasized. Discussions included future advancements in multi-material printing and bioprinting that could open new frontiers.

Impact on My Engineering Perspective

Attending the workshop broadened my understanding of manufacturing flexibility and design iteration. It encouraged me to think more critically about material selection and production constraints in my projects. This experience enhanced my problem-solving skills and inspired me to explore additive manufacturing in future engineering challenges.

Key Takeaways

The most valuable lessons from the workshop include the importance of design for manufacturability, patience in troubleshooting, and continuous learning. For beginners, starting with simple designs and gradually exploring complex geometries is recommended. Embracing failure as part of the learning process is essential to mastering 3D printing.

Conclusion

Overall, the two-day 3D printing workshop was an enriching experience that deepened my technical understanding and expanded my creative horizons. It complements my broader interests in engineering and design, equipping me with practical insights to innovate and prototype effectively in my future endeavors.